Been quite some time since the last post, mostly because life has been a mess. Since my last post, I joined an Improv comedy class and had my first show (a warm hi to all my fellow improvers at Bay Area Acting Studio), planned for and moved completely across the country (from Silicon Valley to Pensacola, Fl), helped stand up a new IT training school for the US Navy, and completely refurnished a new house (which is still somewhat in-progress). I’ve got a lot of stuff to say about a lot of different things, but I still really don’t have time to say any of them, as I am currently still working 70+ hour weeks and every single weekend (it’s been three months now, which might be a new record). However, there’s one thing I absolutely had to post, because it’s the single best gift I think I’ve ever been given: A coffee table and lamps made from the 4.6 V8 engine out of a mustang GT.

I have had this idea percolating in my brain ever since I saw the V12 coffee table on Top Gear, but I’ve not pursued it because I suspected it was more difficult than it sounded. Luckily, my brother (Jason Hill from Shmikey’s Performance) is a mechanic and perfectionist with a creative streak, and he got really into the idea when I presented it to him. I expected good work, but what I got blew me away.

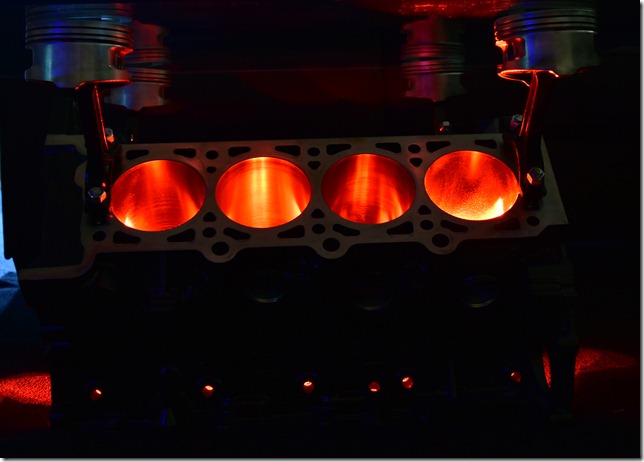

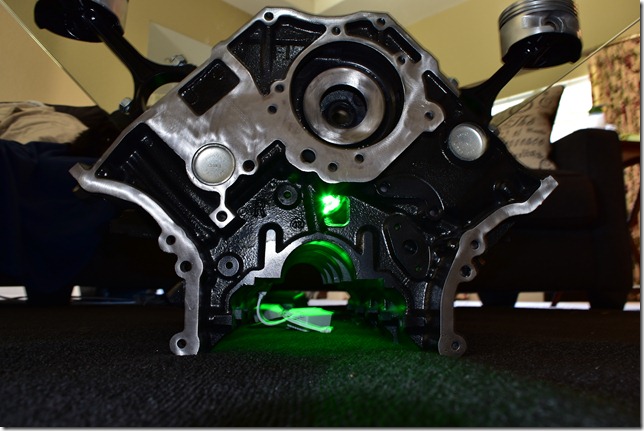

Jason took the 4.6, stripped it down, sandblasted it, and then hot baked it to get all of the oil out of the metal. He then primed and painted the block gloss black, and installed all new freeze plugs. Next, he hand polished all of the exposed metal to make the aluminum shine, and clear coated it to keep rust out.

To hold the glass, he took the rods and bolted them into the top of the block. He actually had to fabricate a way to do this, since the head stud holes don’t line up on a 4.6; they are offset on the right and left banks. The pistons were similarly hand-polished and clear coated.

As if this wasn’t enough, he finished the build by putting a programmable LED light controller with a remote inside the block, so that the light shines through the cylinder bores. He topped the whole thing off with a laser-etched plaque and a 1/2” thick piece of custom-cut glass.

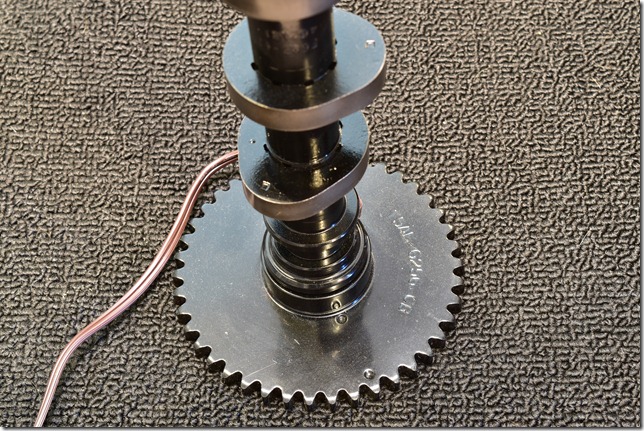

However, since he already had a pair of cams from the engine, he figured he might as well put those to use, so he decided to make some lamps.

He first welded the cam sprockets to the cams to provide a base, then he drilled out the cams to run the power wire.

He also treated the cams to the same process as the block – sandblasting, hot baking, painting. He finished the lamps off with a chain pull that ends in a little metal turbo.

Anyhow, if anyone is interested in getting one of these, he said he would have no problems building more. Just get in touch with him through his Facebook page.

Recent Comments